Industrial excellence

With over 60 years' expertise in the Pharmaceutical, Veterinary, Medical and Diagnostic markets, Union Plastic draws on its technical know-how in plastic injection moulding to develop ever more effective products.

Mono plastic injection moulding and injection blow moulding

More than 100 presses

Manufacture of prototype moulds and integrated maintenance

Strategic file confidentiality

Optimised automated or manual assembly

More than 25 automated lines with robots

Creation of complex products containing up to 12 parts

Optimising performance and tool guarantees

Your partner in bringing your new projects to fruition

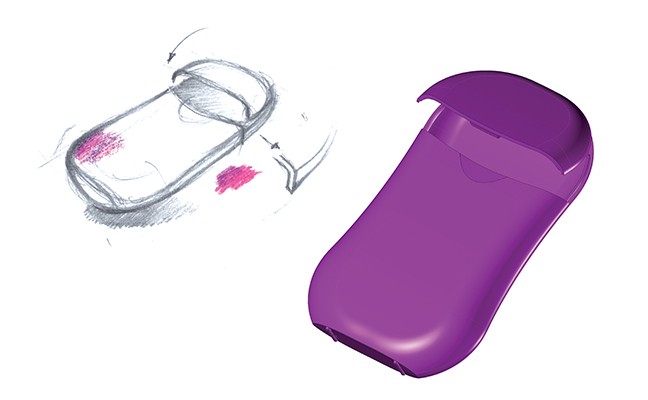

More than 30 concepts proposed each year. Our design team works in partnership with your R&D and Marketing departments to jointly develop the concepts of your future products.

More than 20 industrial developments completed each year. Union Plastic possesses a dedicated development team comprised of project managers, developers and metrologists.

Co-development of your products and consumables

Qualification of manufacturing processes

Integration of existing tools

Together, looking to the future

We integrate all forms of expertise in a qualified system, from initial analysis of your requirements to validation of pilot runs:

- Needs and risk analysis

- CAD, Computer graphics, Rheological studies

- Mock-ups

- Internally created prototype moulds

- Material source selection

- Validation pilot runs

4 Back-up production sites

Union Plastic products are manufactured in a secure environment. Our 4 Back-Up sites, 3 in France and 1 in Tunisia enable us to offer complete solutions based on flexibility and competitiveness.

Our cutting edge clean room production lines (ISO9 - ISO8 ISO7 areas) are organized into 6 performance units to meet all your needs in terms of reactivity and results.